Some of basic Information about Insulator

- Different types of insulators are used to prevent the flow of current to the earth from the transmission line.

- Insulators play an important role in the successful operation of the line.

- In bare conductors, primary insulation is provided by the air between conductor to conductor and between conductors to earth.

- At the point of mechanical support, insulators are provided.

- In low voltage, a line such insulators are relatively simple but at Extra High Voltage and extra High voltages they are complex.

Requirement of an Insulator

- Mechanically strong

- High Dielectric Strength

- Provide High Insulation Resistance to leakage current.

- Free from internal impurities

- Should not be porous

- Must not allow gases or liquid into the insulation material

- Not affected by the change of temperature

- A high ratio of puncture to flash over voltage

Types of Insulators Based on Material:-

- Porcelain

- Glass

- Steatite

- EPDM rubber

- Pin Insulator

- Disc Insulator –Suspension –Starin

- Post-Insulator

- Long Rod Insulator

- Shackle Insulator

- Guy Insulator

Types of Insulators Based on Voltage:-

- L.T.

- 11 KV

- 33 KV

- 132 KV

- 220 KV

- 400 KV

What is an Insulator?

The substance through which the current can’t pass easily is known as an insulator.

Necessity of Insulator on O.H. lines

In overhead lines, the insulators are used to hold the bare conductor that carries the voltage and current from one point to another without fail.

Insulating Materials

- Porcelain

- Glass

- Fiber

- Mica

- Rubber

- Wood

- Asbestos

- Empire Cloth

- Leather Oil paper

- Bakelite

- Synthetic such as polymeric

Mainly our insulators are made from glazed porcelain and tough glass.

Types of Insulator

There are mainly five types of insulators used as overhead insulator likewise

- Disc Insulator

- Pin Insulator

- Shackle Insulator

- Stay Insulator

- Post type Insulator

-

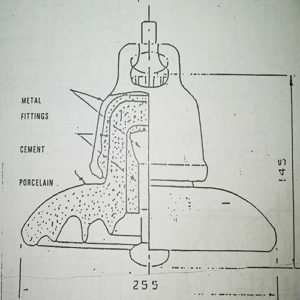

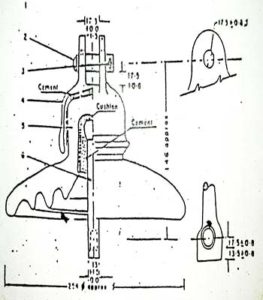

Disc Insulator (Strain or Suspension type)

It is an insulator stringing the conductor o 11KV , 33 KV, 132 KV and above by the help of hardware fitting on the terminal points. Also, hold the conductor on suspension position on H.V. and E.H.V. tower with the help of suitable clamp or straps.

It is also two types

- Ball & Socket

- Tongue and Cleaves

Generally ball & socket types are used for 33KV and above and T & C disc used on 11 KV line.

N.B.– Ref the diagram of B & S, T & C disc insulator.

Specification

- Insulator I.S. 731.1971

- Insulator Fittings I.S. 2486 (part-i) 1971

I.S. 2468 (part-ii)

Technical Details

- Highest system voltage in kV Rms…….. 12 kV (rms)

- Wet power frequency withstand test in kV Rms………(35 kV (rms)

- Power frequency puncture withstand test in kV Rms …….105 (rms)

- Impulse voltage withstand test peak……..75 (peak)

- Creepage distance at the highest system voltage

Normal and moderate polluted atmosphere in mm …230 mm - Minimum failing load in KN……….. 45

[ultimatetables 2 /]

Creapage Path

The zigzag distance from line path to earth of insulator is called creapage distance.

-

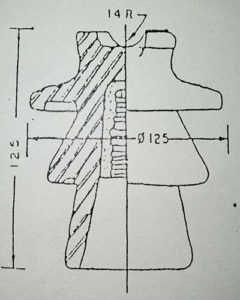

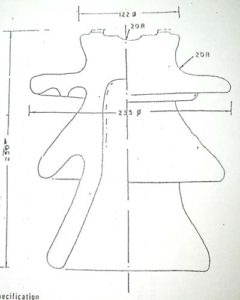

Pin Insulator

Pin Insulator is an insulator consisting of a single of a page of porcelain. It is intended to be mounted rigidly on a supporting structure by a pin which goes inside the insulator. The pin type insulator shall have a top groove and shall be threaded to take mild steel pins.

N.B.- Ref the diagram of L.V., 11 KV & 33 KV pin insulator & G.I pins.

Specification

- Insulator 731.1971

- Insulator fittings is 2486 (part-1) 1971

is 2486 (part.11) 1974

Technical Details

- Highest system voltage in kV Rms…… 12

- Wet power frequency withstand test in kV Rms……..35

- Power frequency puncture withstand test in kV Rms……..105

- Impulse voltage withstand test in peak……….75

- Creepage distance at the Highest system voltage

(a) Normal and moderate polluted atmosphere in mm……..75 - Minimum failing load in KN …………..5

- Store code no……H200713

- Weight in Kg…… 1.9 (approx)

Specification

- Insulator I.S. 731.1971

- Insulator fittings I.S. 2486 (part i) 1971

I.S. 2486 (part.ii) 1974

Technical Details

- Highest system voltage …………36 kV (rms)

- Wet power frequency with stand test ….75 kV (rms)

- Power frequency puncture with stand test………………..180 kV (rms)

- Impulse voltage with stand test …….170 kV (peak) Store code No. H 200759

- Minimum failing load………..10 KN

- Creepage distance at highest system voltage ……………. 36 KV

- Normal and Moderately polluted atmosphere …… 580 mm

- Havily polluted atmosphere………………………….840 mm

-

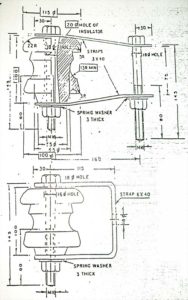

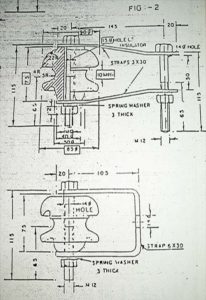

Shackle Insulator

Shackle insulator is an insulation consisting of a single piece of porcelain. It is intended to be mounted vertically or horizontally between and in contact with the two ends of a “U” strap or a pair of straps with its axis vertical. Intended to secure a line conductor in tension. Generally used in L.V. line only. These are 1 & 2 types.

Maximum failing load is 11.5 K.N. & 16 K.N.

N.B. – Ref the diagram of 2 types of shackle insulator with “U” clamp & straps.

-

Stay Insulator

Stay insulators are used in guys. If the live conductor come in to contact with the stay wire and continues to be in contact with it and the line does not trip then the bottom portion of the stay wire would have no voltage due to the insulator provided.

L.T, stay insulators are “A” type & its minimum failing load is 44 KN.

H.T. stay insulator are “B” type & its minimum failing load is 88 KN.

In case of 33KV two numbers of “C” type stay insulators are provided in series.

-

Post Type Insulator

This type of insulator is only used in 11KV & 33KV A.B switches and D.O. fuses. We can use such type of insulator for the jumpering purpose. In sub-statin yard test value is same.

General Requirements for Porcelain Insulators

- The porcelain shall be sound, free from defects, thoroughly vitrified and smoothly glazed.

- The glaze shall be brown in colour. The glaze shall all the porcelain parts of the insulator except those areas that serve as supports during firing or are left unglazed for the purpose of assembly.

Why porcelain Insulators are brown colour glaze ?

- To identify the fault in the insulation top

- The flow of rainwater easily

Faults of Insulators

- Earth leakage (Insulation week)

- High Voltage

- Improper glaze

- Cracking of insulator

- Flash Over

Test (Insulation Resistance)

In pin & disc insulator more than 50 M & merged by 1000V megger.

Ref. show practical

[ultimatetables 3 /]